WhiteWings - Pre-cut Volume 2 Excellent Gliders 1992

This worklog covers the fabrication of whitewings type paper airplane models reproduced from original kit designs. If you are uneasy with reproducing 30+ year old out-of-print paper model kits, then turn back now.

materials and tools

3/32" balsa sheet, 3 inch width

85lb 230gsm cardstock, joyberg brand

hobby knife

laser cutter, 40W CO2

White glue, Elmer's

Straight edge

Flatbed scanner

Software - GIMP, Inkscape, CorelDraw 12 (for driving laser)

A new, unused "Pre-cut Volume 2 Excellent Gliders" kit published in 1992

For details on material selection and research see my "whitewings" article under lab notes.

process

I scanned the original, "un-punched" paper and balsa sheets as grayscale documents to retain part number markings. I can also print the originals and then hand cut the components.

However, the goal is to create vector files from the original sheets that I can use with my laser cutter for maximum repeatability and fidelity. To digitize the components I punched the pieces out from their sheets and scanned the punched sheets against a black background as black and white documents. By scanning as black and white docs it minimizes image artifacts and makes the edges as crisp as possible.

Then I cleaned up the scans in GIMP to remove speckles, and smooth edges.

I then imported the scans to Inkscape to trace the bitmaps and create .SVG vector files. I imported the .SVG files into CorelDraw and smoothed the edges and curves. I also added notches and tiny circle cutouts to indicate center lines, bend lines, balance points, and alignment indicators.

observations and testing

As of July 14 2024 We have two models digitized, cut, and assembled - Light Plane 307, and Racer 536 Swallow.

June 30 2024

The first paper and balsa model I've scanned and converted to vector graphics is the Light Plane #307 (see figure 1). I constructed the original which was easy to assemble as expected from a "pop-out" kit. I cut components for a second plane using my laser which I'll refer to as 307x. I used 80lb Accent Opaque cover cardstock and 3/32 in. balsa sheet from a local hobby shop.

The quality of the original balsa is much better than what I selected at the hobby store. It is much harder and denser. It appears to be A grain- it bends readily across the grain but is very stiff along the grain. The face shows long grain lines and the edge grain shows ray patterns. It has a measured density of 0.236 gm/cm3 (14.8 lbs/ft3).

The hobby store balsa has a measured density of (TBD). It appears to be B grain - the face grain lines are shorter and it flexes easily along the grain.

Update July 3 2024

Light plane 307 from the original kit has a mass of 6.58 grams, while 307x comes in at 5.15 grams - significantly lighter. I expect most of that is from the much less dense balsa.

307x flew well in indoor testing. However, after several flights the fuselage shattered on impacting a sofa cushion (see figure 2). This highlights the need for sourcing better quality balsa. Also, the 80 lb/215 GSM cardstock is not as stiff as the original material with a measured density of 230gm. I sourced 85 lb/230 GSM mystery brand cardstock.

Update July 8 2024

I measured the paper stiffness by supporting the sheets on supports, applying a 50 gram weight and then measuring the distance from the table surface to the lowest point of the paper. My testing setup used wood blocks spaced 128 mm apart. Stiffer papers will deflect less and thus the distance from the table surface to the paper will be larger. The original and the 85 lb/230 GSM card both measured 50 mm. The 80 lb / 215 GSM card measured 47 mm.

The 85 lb card matches the stiffness of the original material and has a smoother finish quality. The 80# material has a matte surface. The original cardstock has a very smooth surface.

Once I've sourced better balsa I will cut and assemble a new 307x.

Laser cutting soft balsa also produced a lot of smoke and flaring. I'll be upgrading the laser with air assist. A project that has been pending for years, which will be nice to finally finish.

Update July 8 2024

I researched alternate balsa sources. I found a supplier that gives you the option order material by grain type and density. But the cost including shipping is relatively expensive. While analyzing the wreckage of 307x I noticed that the balsa cracked where the paper components were glued to the fuselage. Also, the areas of the fuselage with the paper overlay matched the stiffness of the original 307 fuselage well. This suggests a possible solution to the fuselage structural deficiency - a laminated fuselage consisting of a balsa core sandwiched between two sheets of 230 GSM card stock.

I glued up a sample sheet and will let that cure overnight. If successful it will allow me to use my existing stock of B grain lightweight balsa which is much more readily available. Also, I should be able to cut the laminated fuselage on the laser without issues. I'll measure the density of the cured sheet and see if it's closer to the balsa from the original kit.

Update July 9 2024

Laminated panel dimensions = 77 mm x 217 mm x 3.15 mm Mass = 14.29 gm Density = 0.272 gm/cm3 (16.9 lb/ft3)

The density of the laminated panel is higher than the original kit balsa but the stiffness is similar. I propped panels on blocks spaced 150mm apart and applied a 1000 gm weight, then measured the distance from the table surface to the bottom edge of the panel. Both the original balsa and laminated panel measured 60mm. The B grain balsa measured 58 mm. In the hand the original kit balsa feels stiffer than the laminated panel, but the laminated panel is also stiffer across the grain than the kit balsa. I like the appearance of the laminated panel, as it feels more in keeping with the original all paper WhiteWings planes.

I feel the higher density is will be a fine compromise as long as the fuselage cuts cleanly on the laser.

Update July 11 2024

I tested the laminated panel on the laser. It cut very well. Less flare ups than the raw balsa with no reduction in cut speed. I cut components for two 307 model plans and assembled one which I'll refer to as 307x-1 (see figure 3). The new plane weighs in at 7.31 gm, 0.73 grams heavier than the original kit plane. 307x-1 flies well indoors and didn't require much tuning. After several impacts I found no issues with the structure. The laminated fuselage seems to be holding up well. Next step is outdoor flight tests!

Update July 12 2024

Outdoor flight tests with 307x-1 were a success! The plane flew easily from hand or slingshot launch and even with one solid nosedive into the ground the plane held up very well. We found no issues with the fuselage and the wings and tail didn't distort or bend. Minimal tune-ups were needed between flights. The last flight was a soaring, circling affair that sadly took it over a 10 foot fence and so the plane was lost. But we quickly assembled another from a batch of parts I had previously cut once we returned home.

We're looking forward to more flights with 307x-2. And we've selected the next pane in the kit to scan and cut - the Racer 536 Swallow.

update july 13 2024

Components for the Racer 536 Swallow model have been digitized and cut. We'll assemble a few and test once the hot weather breaks. In keeping with convention the first test model will be named 536x-1.

Update July 14 2024

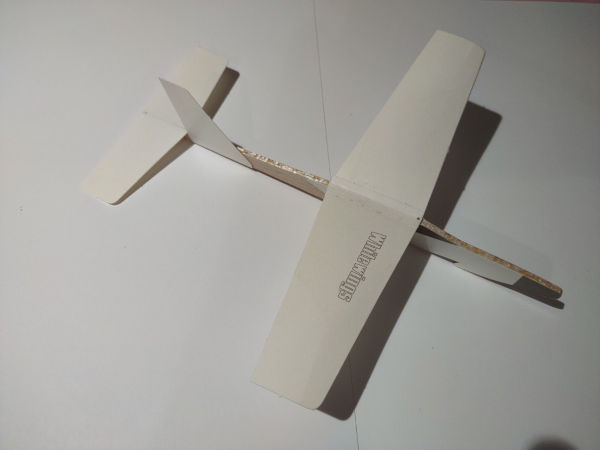

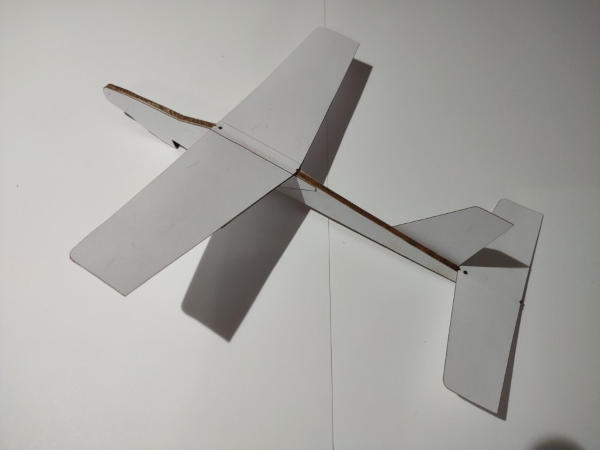

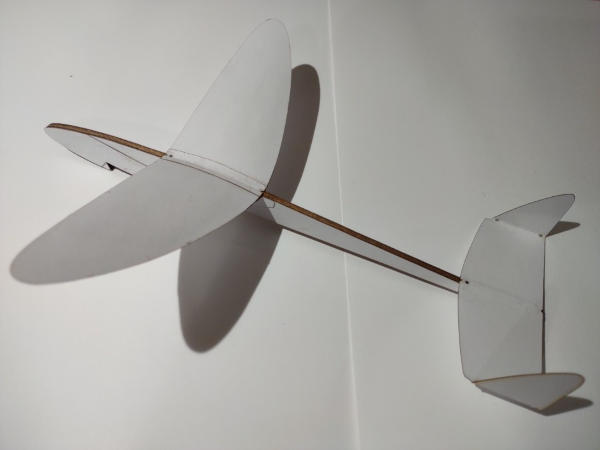

We assembled two 536x models, 536x-1 and 536x-2 (see figure 4). This pane has beautiful lines. A long elegant fuselage combined with lovely rounded wings makes a lovely plane. The indoor flight tests reveal interesting characteristics in the air. The plans seems to "dance" in the air. It dips and swoops gently and with it's strong dihedral wing angle it rocks gently side to side. I think it will be a bit of an acrobat in outdoor flight. In contrast the 307x models exhibit relatively level, steady flight characteristics. In our outdoor flights it tended toward large, steady, sweeping curves.

Figure 1: Original Light Plane 307 from Pre-cut Volume 2 Excellent Gliders - 1992

Figure 2: 307x assembled from laser cut components. Fuselage failed due to lightweight balsa.

Figure 3: 307x-1 assembled from laser cut components. Fuselage cut from balsa and paper laminate.

Figure 4: 536x-1